Joining solid surface

Factory Join – these are used in the production of the worktop pieces before it leaves the factory. Sometimes a section may need to be wider than the standard sheet size (approx. 750mm), for example when making an island top. In this case, a factory join is made.

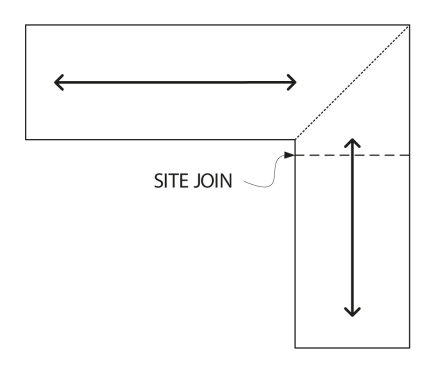

Site Join – these joins are needed for practical reasons where either lifting or fitting of the top becomes impossible if made in one piece. Site joins can’t be done in the corners where there are mitred joins. Where this join occurs, there will be a visual break in the pattern where a site join needs to be created.

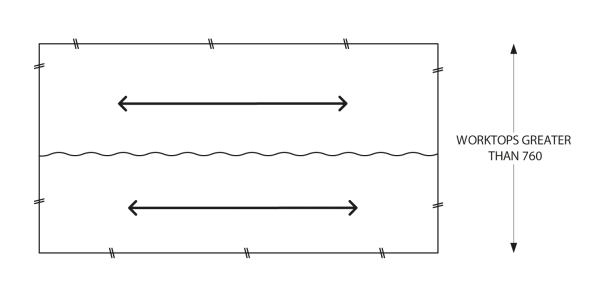

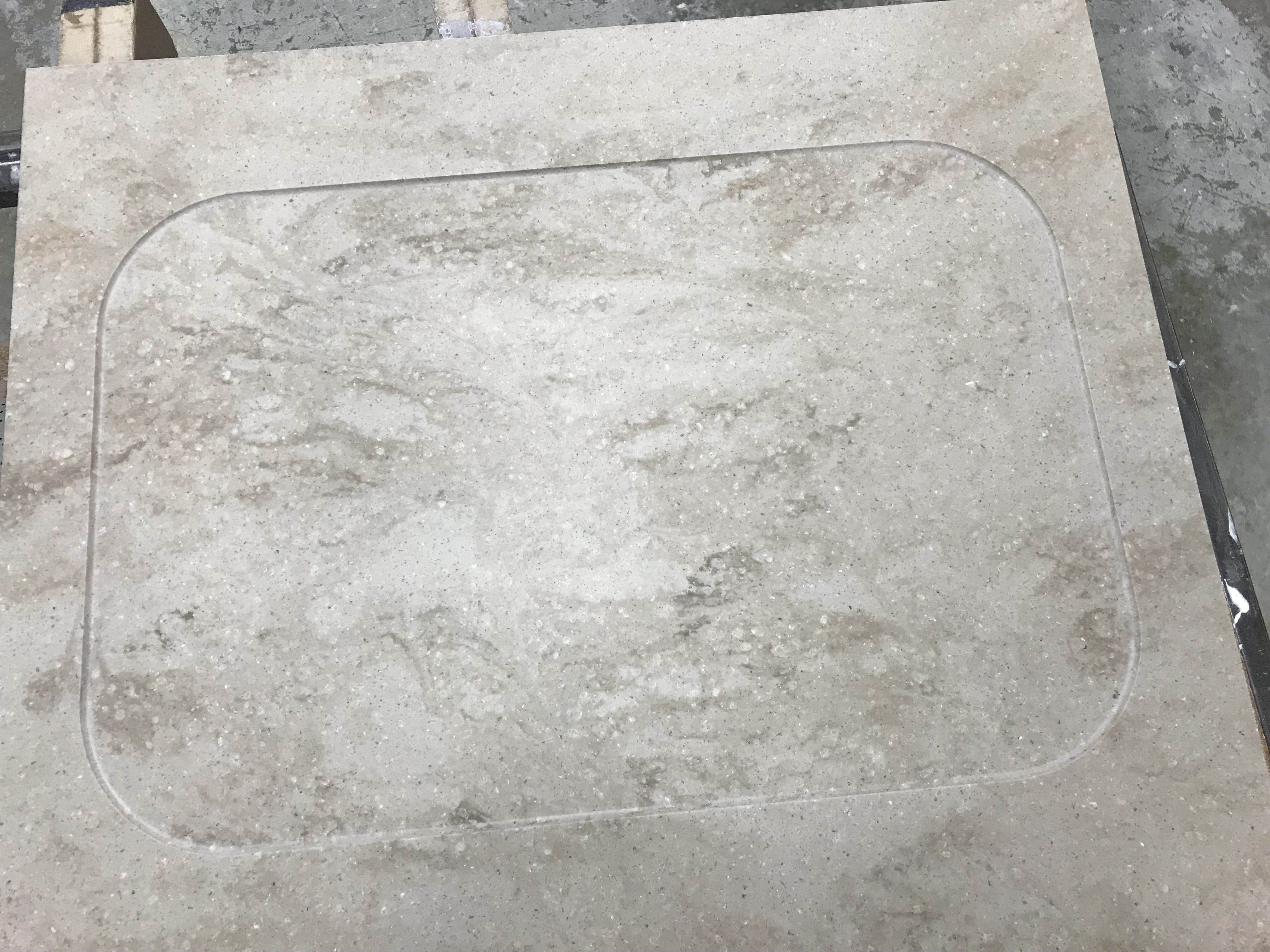

Deeper Tops

Deeper Tops

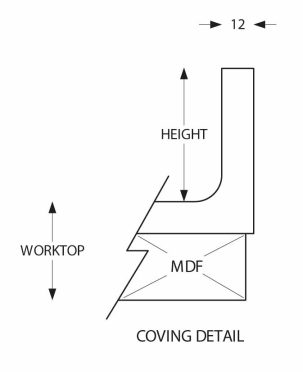

Coved up-stands

Coved up-stands